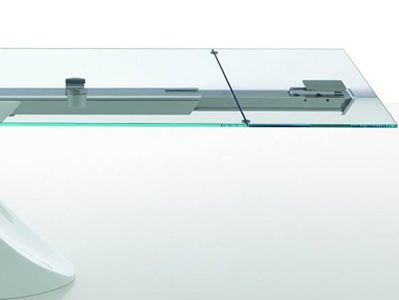

EXCLUSIVE CUSTOM MECHANISMS

PM Aluproget can provide its customers with a complete all-inclusive service for creating extending mechanisms and table legs, from conception to finished product, packed and ready for delivery.

The Design Department lworks closely with the customer. The project is developed by considering all possible solutions to the various functional problems, both static and dynamic, that come up at the design stage. It then proceeds to a production hypothesis and relative cost analysis.

The following steps in particular are carried out and coordinated:

3D CAD design

Analysis of costs

Construction of a Prototype

Development

Management of any moulds to be produced

Production management of templates for profile design

Production of design details

Obtaining standard components

Surface treatments

Assembly

Packaging